Today April 29, 2016 I am please to say the Barn construction is done. We are waiting for Dominion Power for electricity.

Finally progress! The Hardi-board arrived damaged again, however, the supplier gave it to us for free and we have enough to do the

money side of the barn, the rear doors will be completed with MDO and painted with color-match paint. It will still look like it was planned that way.

color-match paint. It will still look like it was planned that way.

The construction details are below.

The barn construction began on January 5, 2016, The footer was dug 18-inches and inspected and the concrete was poured.

The following day the batten boards were installed by Chad and Mike. On the 7th the concrete block was delivered. On January 12, 2016 the three course of concrete block was

Ever wonder why old barns are usually red in color? Red is (or, perhaps, was) a popular color for barns due not to its color shade but for its usefulness.

Many years ago, choices for paints, sealers and other building materials did not exist. Farmers had to be resourceful in finding or making a paint that would protect and seal the wood on their barns. Hundreds of years ago, many farmers would seal their barns with linseed oil, which is an orange-colored oil derived from the seeds of the flax plant. To this oil, they would add a variety of things, most often milk and lime, but also ferrous oxide, or rust. Rust was plentiful on farms and because it killed fungi and mosses that might grow on barns, and it was very effective as a sealant. It turned the mixture red in color. When paint became more available, many people chose red paint for their barns in honor of tradition.

installed leaving space for two 10-foot barn doors and a 36-inch side entry door. The first shipment of lumber was also deli vered. Today January 13, 2016 the concrete contractor returned to scrap the topsoil from the barn making the soil even with the top of the footer.

vered. Today January 13, 2016 the concrete contractor returned to scrap the topsoil from the barn making the soil even with the top of the footer.

Work continues on the barn with framing, and sheathing being added, in addition the two front to back lam-beams are in place. Saturday we picked up the door that was ordered and the windows will come in in about a week. We had rain and some snow over the weekend so hopefully work will continue on Monday (1/18). Well we got some snow over the weekend, the Northeast is referring to it as the Blizzard of 2016. WE got 12-inches in Richmond but far less in New Point. Construction continues on the Barn regardless of the weather.

The barn door hardware has arrived and will be delivered tomorrow 1/26/16.

Work continues on the bard, the framing is

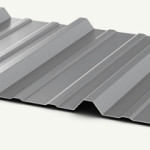

almost complete. The roof sheathing is on and we have decided to go with a metal roof from

Union Corrugating we have also added a cupola and a weather vane

to the project from Valley Forge Cupolas. Tarpaper was installed late in the  afternoon in anticipation of rain tomorrow (2/3/2016).

afternoon in anticipation of rain tomorrow (2/3/2016).

Progress continues (2/8/2016) with the addition of soffits and trim, including soffit end boxes to provide a more finished look and  to match the Bunkie construction elements. Today Pat tried to hi-Jack my barn door windows, however we decided to purchase new windows, only slightly smaller (20″x48′) that are awning style that open for additional ventilation. There will

to match the Bunkie construction elements. Today Pat tried to hi-Jack my barn door windows, however we decided to purchase new windows, only slightly smaller (20″x48′) that are awning style that open for additional ventilation. There will be two on each side. We also reworked the stair design to the second floor to the outside to increase interior square footage.

be two on each side. We also reworked the stair design to the second floor to the outside to increase interior square footage.  I also added lights to the cupola which should look very cool when the barn is done. Work continues on the barn (2/18/2016) as the side window has been installed and the openings cut in the second floor f

I also added lights to the cupola which should look very cool when the barn is done. Work continues on the barn (2/18/2016) as the side window has been installed and the openings cut in the second floor f or the windows and entry door. The siding is going on as well. The second story of the barn will be used for storage and we have decided to opt for an internal VersaLift for moving items to the storage area avoiding the stairs.

or the windows and entry door. The siding is going on as well. The second story of the barn will be used for storage and we have decided to opt for an internal VersaLift for moving items to the storage area avoiding the stairs.

To provide the look of an old barn I decided to install a Hay Track Beam and a double pully for the barn. The beam was constructed from oak that was 1-¾” by 7″ by 8 foot long. I glued two piece together to give it more of a beefy structure (7″x4″) and then doweled the two pieces together to

constructed from oak that was 1-¾” by 7″ by 8 foot long. I glued two piece together to give it more of a beefy structure (7″x4″) and then doweled the two pieces together to

provide more of a post and bean construction look.

The windows for the second story have

arrived and the steel for the roof is in as well so things should move along pretty quickly from now going forward. The windows for upstairs were installed, however, closer inspection of the roofing showed the distributer shipped the incorrect color, Pearl Gray Vs. Charcoal Gray and the flashing was a mix of both. So much for quality control! Yesterday the ledger board for the rear entry deck was hung and the rail mounting board were hung and wrapped in aluminum in

preparation for the barn door railing system. I also discovered I ordered more door hangers than needed so I can take some back.

Were presently in a rain delay (2/24/2016) with work happening as the team can fit it in. UPDATE (3/6/2016) Between the weather (rain) and supplier progress has been at a stand still. The incorrect color roof and the Hardi Panels were delivered broken beyond useable even if we were willing to absorb the problem. We’re hoping this coming week of beautiful weather will bring better luck. Until the barn is completed we are unable to begin the relocation process from Richmond to empty the garage.

The roofers arrived yesterday and began the job of installing the metal roof. We needed 98″ of run on the upper roof so we had to order 10′ panels and cut them down by 22″, my plan is to use them for the chicken coop which I will build this summer.

Cupola being installed on the barn (3/11/16) The next step is to pour the concrete floor in the barn.

The roofer working on the final section, its been difficult with the 13MPH winds out of the southwest gusting to  27MPH holding a sheet of steel is like being launched off an aircraft carrier. Today March 28, 2016 the concrete is being

27MPH holding a sheet of steel is like being launched off an aircraft carrier. Today March 28, 2016 the concrete is being

poured for the

slab in the barn. Of course it rained for 2 days meaning the the truck will tear up the yard around

the barn. Well here we are and it April 5, 2016 and were still waiting on a delivery of Hardi-board for the barn doors. The doors are complete and hanging on the barn however we can not proceed due to damage in shipment for the second time. The replacements are due with tomorrow or Friday. The plan “B” is to scrap the hard-board and use MDO plywood and paint with a match to the siding.

Weather stripping arrived today from Sealeze. The strips will be applied to all sides of the doorway and the bottom of the door to create more of an weather protected environment.

Mean while Pat has a project of her own going. Well the saga continues, the door windows are installed and the aluminum is on the inside opening but still no Hardi-Board. I will be stopping at M&M next week to have a chat with the owner. With plans to renovate the old cottage and an estimated material cost of well in excess of $100K being treated like a second class customer is totally unacceptable!